Dynamic Compaction: What is it?

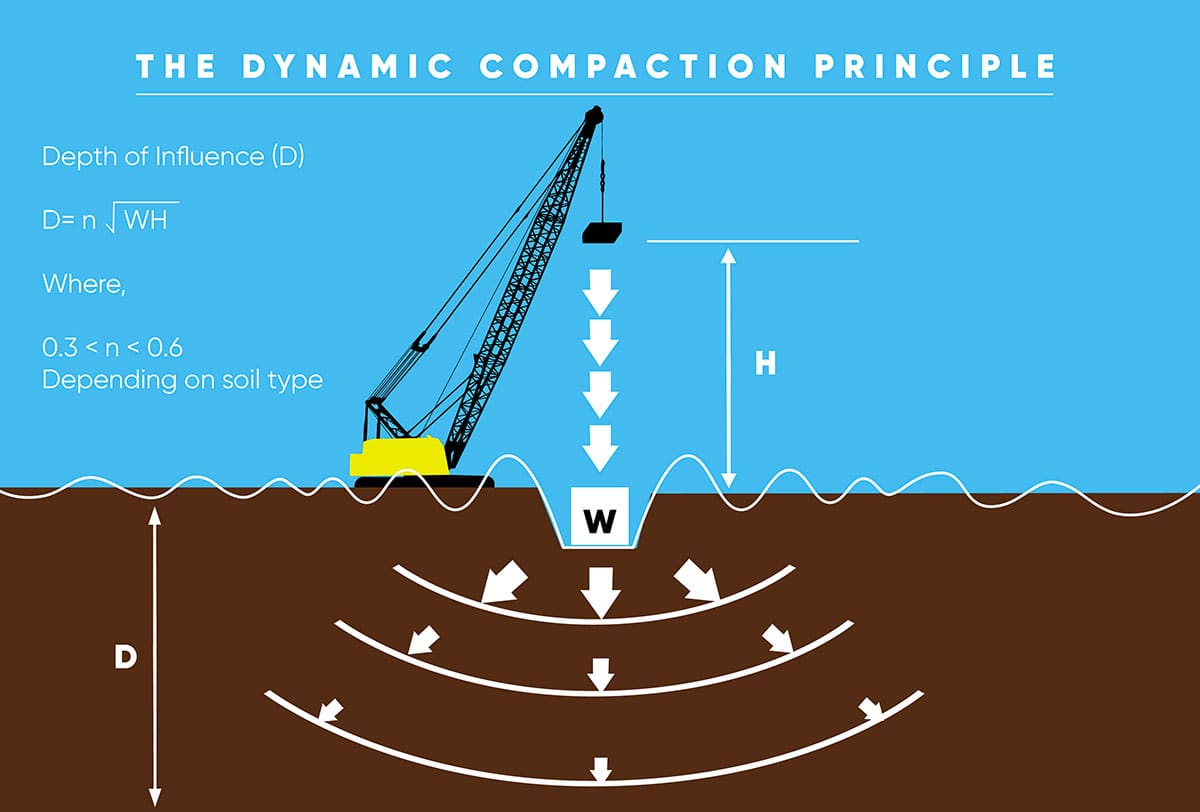

Dynamic Compaction is the introduction of multiple passes of high energy impacts at ground level by repeatedly dropping steel tampers of 6 to 30 tons from drop heights of 30 to 100 feet. This high level impact creates a shock wave that increases and improves the density of the soil and reduces the void ratio, exposing loose zones and soft spots throughout the process. In doing so, the need for off-site removal of the existing soils for replacement with compacted granular fill or implementation of more costly ground improvement or deep foundation options can be reduced or eliminated.

The degree of soil improvement depends on the total amount of energy applied to the soil; the more energy imparted to the soil, the greater the level of improvement. The depth of improvement is correlated to three things: the amount of weight being dropped, the height from which it is dropped, and the nature of the soil being improved.

Dynamic Compaction: What is it?

Dynamic Compaction is the introduction of multiple passes of high energy impacts at ground level by repeatedly dropping steel tampers of 6 to 30 tons from drop heights of 30 to 100 feet. This high level impact creates a shock wave that increases and improves the density of the soil and reduces the void ratio, exposing loose zones and soft spots throughout the process. In doing so, the need for off-site removal of the existing soils for replacement with compacted granular fill or implementation of more costly ground improvement or deep foundation options can be reduced or eliminated.

The degree of soil improvement depends on the total amount of energy applied to the soil; the more energy imparted to the soil, the greater the level of improvement. The depth of improvement is correlated to three things: the amount of weight being dropped, the height from which it is dropped, and the nature of the soil being improved.

Dynamic compaction is normally performed over a grid pattern to allow a consistent amount of energy to be applied to the underlying soils while at the same time looking for areas of differing ground response. Differing ground response normally shows itself in the form of different crater depths; observing this in real time allows for adjustments to the program in the field as the work is taking place. The grid spacing, number of drops per impact point, drop height, and total number of passes depends on the amount of energy necessary to address the site-specific conditions. After each pass, the craters are leveled and compacted to allow for subsequent high-energy applications.

The tamper used in the dynamic compaction process is usually 5 to 6 feet in diameter, but can have widely varying contact pressures; the type of weight used on each job is tailored to the specific in situ soil conditions.

Dynamic compaction is normally performed over a grid pattern to allow a consistent amount of energy to be applied to the underlying soils while at the same time looking for areas of differing ground response. Differing ground response normally shows itself in the form of different crater depths; observing this in real time allows for adjustments to the program in the field as the work is taking place. The grid spacing, number of drops per impact point, drop height, and total number of passes depends on the amount of energy necessary to address the site-specific conditions. After each pass, the craters are leveled and compacted to allow for subsequent high-energy applications.

The tamper used in the dynamic compaction process is usually 5 to 6 feet in diameter, but can have widely varying contact pressures; the type of weight used on each job is tailored to the specific in situ soil conditions.