The Dynamic Compaction Principle

What is it?

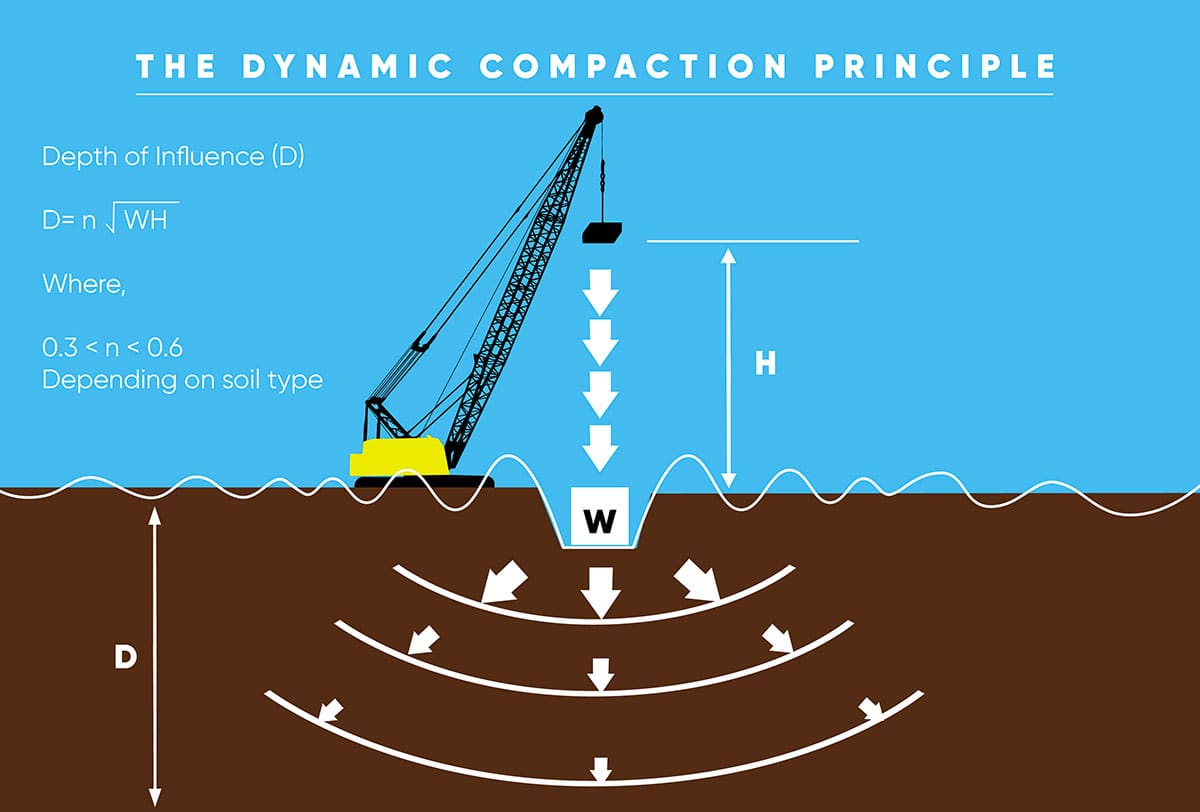

Dynamic Compaction is the introduction of multiple passes of high energy impacts at ground level by repeatedly dropping steel tampers of 6 to 30 tons from drop heights of 30 to 100 feet. This high-level impact creates a shock wave that increases and improves the density of the soil and reduces the void ratio, exposing loose zones and soft spots throughout the process. This can reduce or eliminate the need for off-site soil removal and expensive ground improvement or deep foundation options.

The degree of soil improvement depends on the total amount of energy applied to the soil; the more energy imparted to the soil, the greater the level of improvement. The depth of improvement is correlated to three things: the amount of weight being dropped, the height from which it is dropped, and the nature of the soil being improved.

Dynamic compaction is normally performed over a grid pattern to allow a consistent amount of energy to be applied to the underlying soils while at the same time looking for areas of differing ground response. Differing ground response normally shows itself in the form of different crater depths; observing this in real-time allows for adjustments to the program in the field as the work is taking place. The grid spacing, number of drops per impact point, drop height, and total number of passes depend on the amount of energy necessary to address the site-specific conditions. After each pass, the craters are leveled and compacted to allow for subsequent high-energy applications.

The tamper used in the dynamic compaction process is usually 5 or 6 feet in diameter, but can have widely varying contact pressures; the type of weight used on each job is tailored to the specific in situ soil conditions.

Applicable Soil Types

The soil types that are most favorable for successful dynamic compaction are typically granular soils with low degrees of saturation. However, several soil types can be improved and strengthened using dynamic compaction. These soils and materials include:

Urban or Uncontrolled Fills

This is the most common soil condition where dynamic compaction is used. Dynamic compaction is incredibly effective at improving the stability and reliability of the soil conditions as well as improving the engineering properties. It is quite common for fill materials to contain debris which can create voids, leading to settlement under the placement of new fill or new foundation loads.

Urban or Uncontrolled Fills

This is the most common soil condition where dynamic compaction is used. Dynamic compaction is incredibly effective at improving the stability and reliability of the soil conditions as well as improving the engineering properties. It is quite common for fill materials to contain debris which can create voids, leading to settlement under the placement of new fill or new foundation loads.

Liquefiable or Loose Soils

In instances where loose sands or granular soils are present below the water table, a dynamic compaction program can be implemented to increase the density of the soil below the water table, reducing the chance of liquefaction-induced deformations during seismic events.

Liquefiable or Loose Soils

In instances where loose sands or granular soils are present below the water table, a dynamic compaction program can be implemented to increase the density of the soil below the water table, reducing the chance of liquefaction-induced deformations during seismic events.

Landfill Materials

At municipal solid waste (MSW) sites, dynamic compaction has proven to be a successful option for collapsing voids within the waste, which reduces the amount of oxygen available to create long-term degradation. It also collapses the existing elevation in active landfill settings, gaining air space for importing additional refuse. More recently, dynamic compaction of MSW materials has allowed lightly loaded structures to be founded on the improved soil mass with excellent building performance.

Landfill Materials

At municipal solid waste (MSW) sites, dynamic compaction has proven to be a successful option for collapsing voids within the waste, which reduces the amount of oxygen available to create long-term degradation. It also collapses the existing elevation in active landfill settings, gaining air space for importing additional refuse. More recently, dynamic compaction of MSW materials has allowed lightly loaded structures to be founded on the improved soil mass with excellent building performance.

Mining Spoils

Mining spoils have historically been managed in uncontrolled ways following mining operations. Oftentimes these uncontrolled deposits range from 50 to 100 feet or more in depth. Dynamic compaction has been used successfully at many mine spoil sites. The process of dynamic compaction creates a compacted soil “mat” within the upper 20 to 25 feet of the existing soil mass that greatly irons out settlement resulting from deep-seated compression of the soil column.

Mining Spoils

Mining spoils have historically been managed in uncontrolled ways following mining operations. Oftentimes these uncontrolled deposits range from 50 to 100 feet or more in depth. Dynamic compaction has been used successfully at many mine spoil sites. The process of dynamic compaction creates a compacted soil “mat” within the upper 20 to 25 feet of the existing soil mass that greatly irons out settlement resulting from deep-seated compression of the soil column..

Collapsible Soils

Collapsible soils exist in many areas, particularly throughout the Midwestern and Western United States. In a dry state, these soils have adequate bearing capacity and strength; however, they will often collapse when they become saturated. By utilizing dynamic compaction to densify these collapsible materials, the overall void ratio of the soil can be reduced, minimizing the potential for collapse.

Collapsible Soils

Collapsible soils exist in many areas, particularly throughout the Midwestern and Western United States. In a dry state, these soils have adequate bearing capacity and strength; however, they will often collapse when they become saturated. By utilizing dynamic compaction to densify these collapsible materials, the overall void ratio of the soil can be reduced, minimizing the potential for collapse.

Karst (Sinkhole) Sites

Karst is a geologic formation that happens when cavities form in water soluble rock such as limestone or dolomite. The most common manifestation of a karst condition is a sinkhole at the surface. By utilizing high-energy dynamic compaction drops, near-surface sinkholes can be exposed and remediated prior to surface construction.

Karst (Sinkhole) Sites

Karst is a geologic formation that happens when cavities form in water soluble rock such as limestone or dolomite. The most common manifestation of a karst condition is a sinkhole at the surface. By utilizing high-energy dynamic compaction drops, near-surface sinkholes can be exposed and remediated prior to surface construction.